Belong SteelAbraives for Metal Surface Treatment

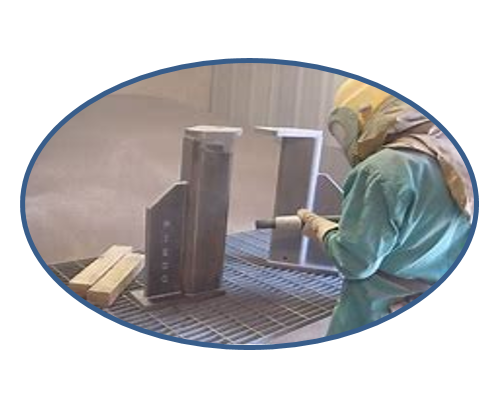

Bearing Steel Grit is a general-purpose manufactured abrasive used to remove thick coatings, heavy rust, and mill scale. It’s fully angular shape cleans by aggressively cutting away at the surface leaving a uniform surface profile. Bearing Steel Grit’s high bulk density, low friability, consistent sizing, and low dust levels provide superior production rates. Bearing Steel Grit is most commonly used in abrasive blasting rooms and mobile steel grit recycling systems and is frequently used for bridge, wind tower, and ship and railcar manufacturing and maintenance.

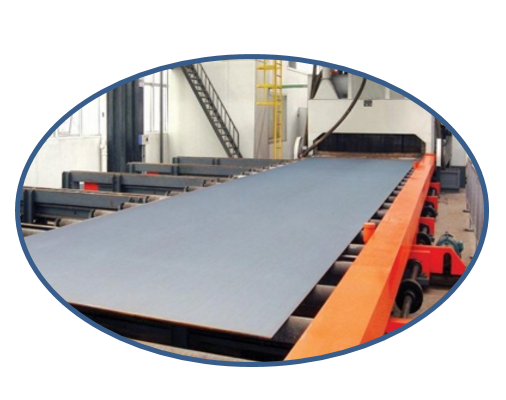

Steel Shot is a general-purpose manufactured abrasive used to remove mill scale and molding sand. Its round shape cleans by hammering the surface, leaving a uniform surface profile. Steel Shot’s high bulk density, low friability, consistent sizing, and low dust levels provide superior production rates. Steel Shot is most commonly used in wheel blast equipment and closed circuit blast systems for steel plate blasting, cleaning castings and forgings, and ship and railcar manufacturing and maintenance.

1. RECYCLABILITY

The low friability of BELONG steel abrasive allows it to be recycled hundreds of times. Unlike mineral or slag abrasives, BELONG steel abrasive will not completely shatter when it hits a surface, keeping its relative size. Recycling BELONG steel abrasive increases profitability by reducing abrasive consumption, and shipping, cleanup, and disposal costs.

2. INCREASED PRODUCTION

BELONG steel abrasive ’s higher bulk density and high hardness results in more energy being transferred to the work surface than mineral or slag abrasives, easily removing thick coatings, heavy rust, and mill scale.BELONG steel abrasive ’s uniform particle size provides consistent coverage and surface finish, increasing production rates.

3. RECYCLABILITY

BELONG steel abrasive ’s durability and low friability produce lower dust levels than most mineral or slag abrasives. Low dust levels improve the operator’s visibility of the work surface, increasing production rates. Lower dust levels also reduce cleanup costs on the job site.

Surface Applications

Used for blast cleaning of casting, die-casting, forging; sand removal of casting, steel plate, H type steel, steel structure.

Rust removal of casting, forging, steel plate, H type steel, steel structure.

Shot peening of gear, heat treated parts.

Shot blasting of profile steel, ship board, steel board, steel material, steel structure.

Pre-treatment of surface, steel board, profile steel, steel structure, before painting or coating.